Climbing System

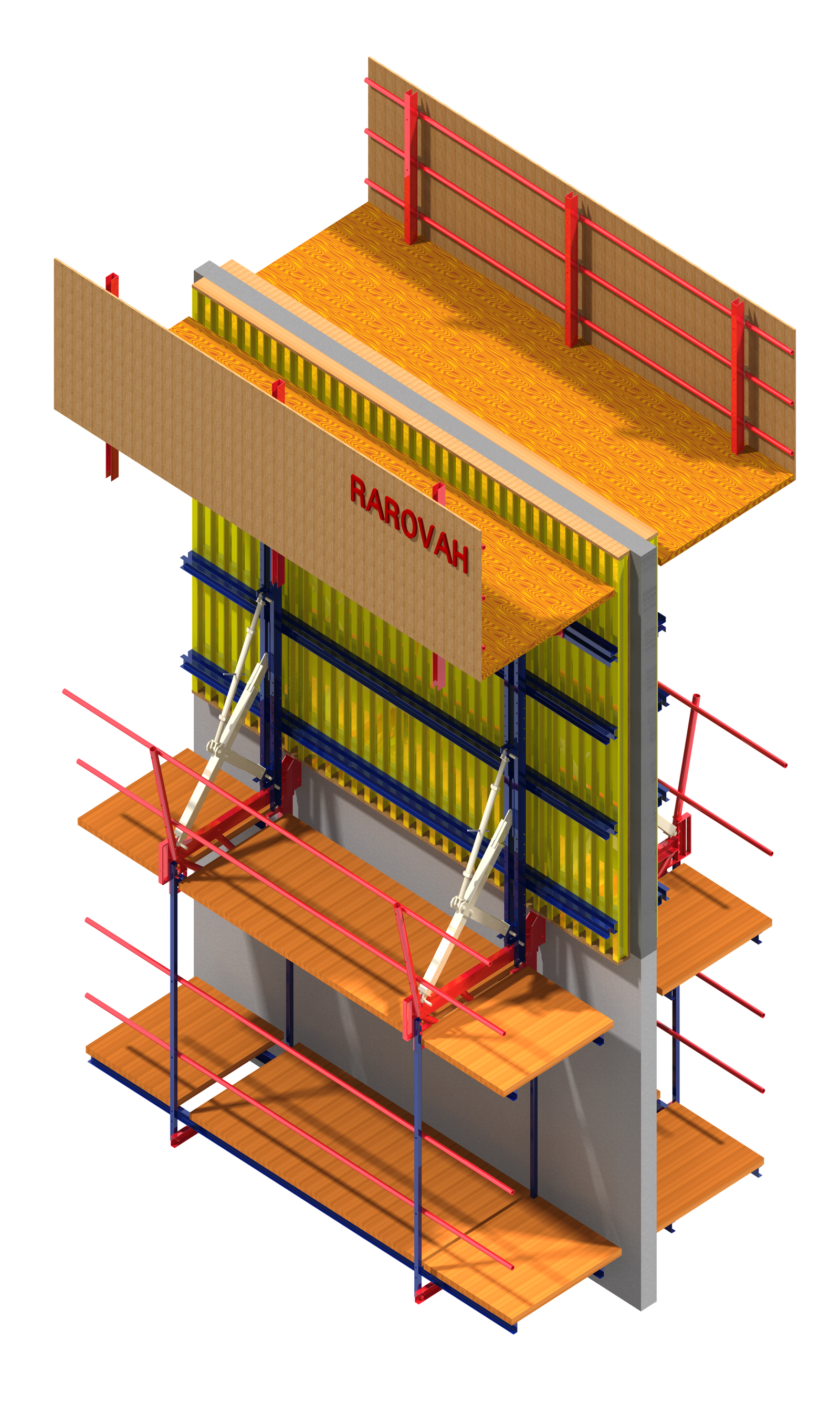

CF25 Crane Climbing Formwork

Climbing Formwork – CF25, is a robust easy to assemble system. Standard platform width of CF25 is 2m. The CF25 Crane Climbing Formwork is a robust and highly mechanized vertical formwork system designed for high-rise and core wall construction. With a standard platform width of 2 meters, it offers ample working space for site personnel and equipment. Each platform spans up to 5 meters and supports shutter heights up to 4 meters, ensuring efficient coverage and reduced setup times. The system is fully crane-handled and easy to assemble, making it ideal for projects requiring rapid vertical progress. Customizable to suit site-specific needs, CF25 provides a safe, adaptable, and cost-effective solution for modern high-rise construction projects.

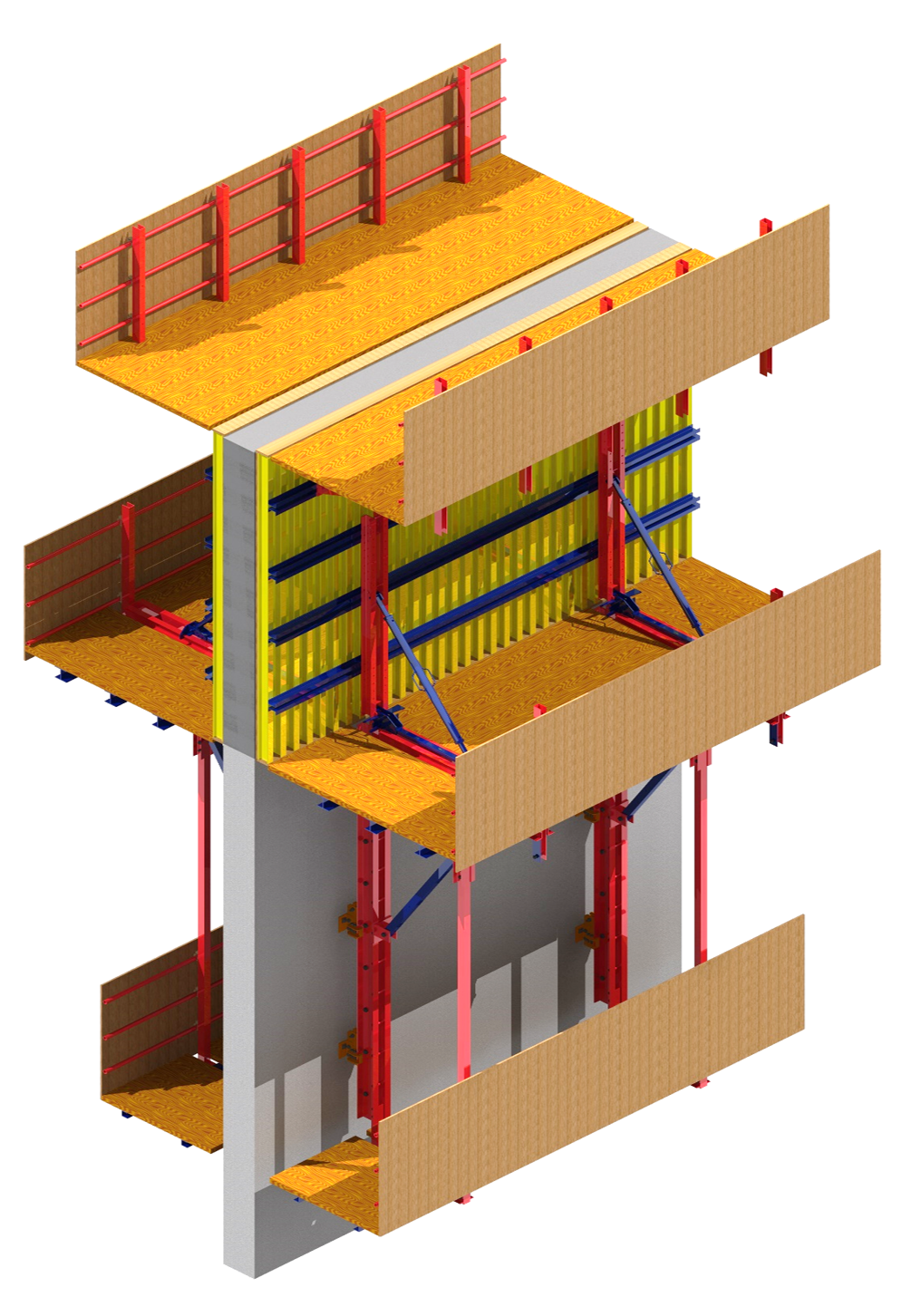

CF50 Automatic Rail Climbing System

The CF50 Automatic Rail Climbing System is a versatile, modular solution designed for both climbing formwork and protection panels in high-rise construction. This rail-guided system ensures smooth, safe vertical movement—even in strong wind conditions—minimizing construction downtime and improving site safety. It can be operated using either a crane or a mobile hydraulic system, offering flexibility to suit varying project requirements. The CF50 system supports rapid floor-to-floor progression and reduces reliance on external scaffolding. Its adaptable design, ease of handling, and enhanced safety make it an ideal choice for core wall construction and fully enclosed working environments.

CF100 Boom Placer Climber

The CF100 Boom Placer Climber is an advanced concrete placement solution integrating a boom placer with an Automatic Climbing System (ACS). Specially designed for high-rise construction, it allows the boom placer to climb in sync with the structure, eliminating dependency on external cranes and minimizing repositioning delays. This system ensures uninterrupted vertical concrete delivery, streamlining the construction process and enhancing site productivity. Its robust design supports continuous operations in challenging environments, improving safety and cycle time. Ideal for core walls, lift shafts, and tall structures, the CF100 is a smart investment for efficient and cost-effective vertical concrete placement.

LSP30 Lift Shaft Platform System

The LSP30 Lift Shaft Platform System is a specialized solution designed to optimize work within elevator shafts during high-rise construction. Offering a stable, secure, and easily installable working deck, it significantly enhances safety and efficiency for construction teams involved in lift installation and shaft-related activities. The modular system is adaptable to varying shaft dimensions and allows seamless vertical adjustment as the structure progresses. With minimal crane dependency and user-friendly assembly, LSP30 reduces downtime and increases productivity. It’s the ideal platform for safe, precise, and uninterrupted execution of elevator and core wall operations in tall building projects.

SCF150 Heavy Duty Crane Climbing System

The SCF150 is a powerful crane-assisted climbing formwork system engineered for heavy-duty applications in high-rise construction. Its self-climbing mechanism enables the structure to ascend with the building, eliminating the need for external scaffolding. Designed to support large loads and wide platform areas, SCF150 is ideal for tall towers, silos, and core wall construction where stability and strength are paramount. The system ensures safe working conditions at height while improving cycle time and construction efficiency. With customizable platform sizes and robust design, SCF150 offers a reliable and scalable solution for demanding vertical construction projects requiring precision and durability.

Wall Column System

TS wall column Formwork System

The TS Wall Column Formwork System is a robust and user-friendly solution designed for forming vertical structural elements like walls and columns. By combining the flexibility of timber with the strength of steel, it ensures high precision, durability, and adaptability on site. A key advantage of the TS system is its standardized components—suitable for both walls and columns—minimizing the need for separate parts and reducing assembly time. Its modular design enhances efficiency, simplifies logistics, and supports repeated use across projects. Ideal for high-rise and industrial structures, the TS system delivers consistent quality, cost-efficiency, and fast construction cycles.

X-Pro Modular Panel System

The X-Pro Modular Panel System is a lightweight, high-performance formwork solution designed to accelerate construction timelines without compromising quality. Constructed from high-strength alloy steel and SG grade accessories, X-Pro ensures durability, safety, and ease of use. Its simplified panel sizing reduces inventory and speeds up assembly on-site. Standard panels are intelligently designed to accommodate complex configurations such as L-junctions, T-junctions, and corners—eliminating the need for custom components. Ideal for columns, walls, and foundations, the X-Pro system delivers excellent surface finishes, enhanced labor productivity, and long-term reusability. It’s the go-to system for fast, flexible, and efficient shuttering in modern construction.

Decking System

*Image Will be uploaded soon

*Image Will be uploaded soon

Table Formwork System

The Table Formwork System is an innovative solution for fast and safe concrete slab construction, ideal for high-rise and large-scale industrial projects. Featuring pre-assembled, large-area tables, the system can be quickly positioned, stripped, and repositioned using cranes—significantly reducing labor and cycle time. Its modular design offers flexibility to adapt to varied slab layouts, while its robust construction ensures long-term durability and safety. Designed for repeated use across multiple floors, the system minimizes material handling and enhances site productivity. The Table Formwork System is your go-to choice for efficient slab casting in modern, large-volume construction environments.

Movable Formwork

Movable Traveling Formwork System

The Movable Travelling Formwork System is a dynamic, high-efficiency solution designed for continuous structures such as bridges, tunnels, and crash barriers. Its mobile framework allows for quick repositioning without disassembly, significantly reducing cycle times and construction downtime. Built with durable materials and adaptable configurations, the system accommodates varying design geometries while maintaining high structural precision. It enhances site safety and productivity, especially in linear infrastructure projects that demand repetitive operations. Easy to operate and cost-effective, the Movable Travelling Formwork System is engineered to deliver consistent quality and speed, making it an ideal choice for streamlined, large-scale infrastructure development.

Safety System

Access Stair tower System

The Access Stair Tower System is a modular, secure solution for vertical movement in construction and industrial environments. Designed for quick assembly and flexibility, it enables safe and efficient access across various elevations. The system features anti-slip treads, handrails, and compliant safety features, ensuring worker security in even the most demanding site conditions. Whether used for scaffolding access, public walkways, or emergency exits, it provides a stable and reliable platform. Its modular design supports fast repositioning and integration with other site systems, making the Access Stair Tower System an essential component for streamlined, safe, and organized site logistics.

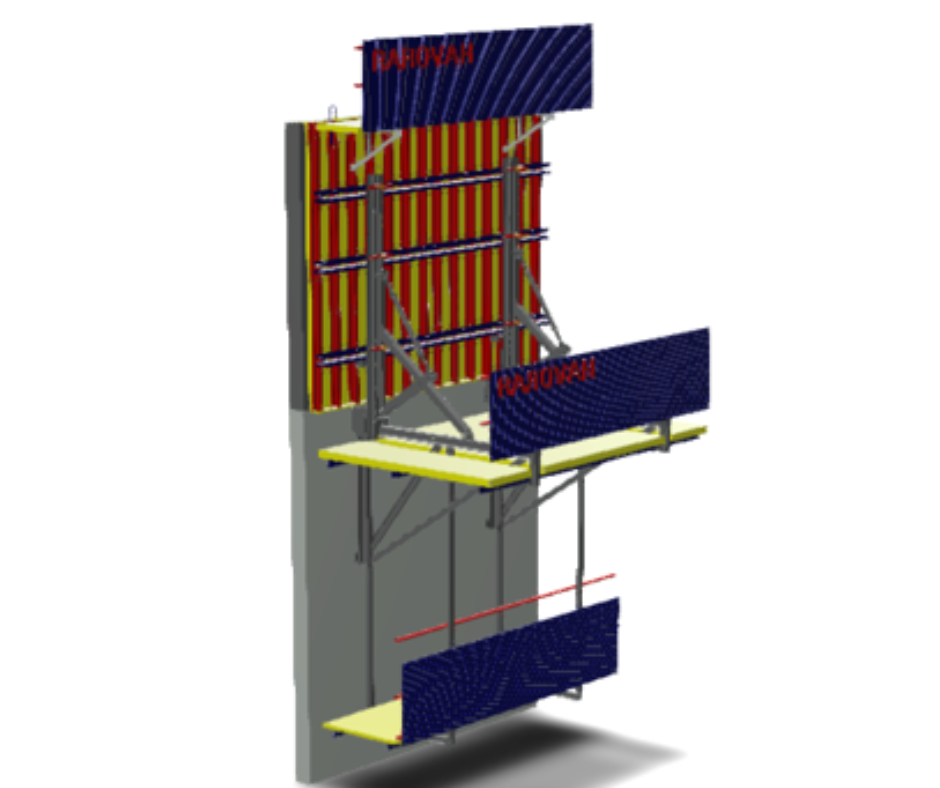

ACS Safety Screen System

The ACS Safety Screen System is a high-performance climbing protection solution engineered to ensure worker safety and site efficiency on high-rise construction projects. Designed to provide a full-perimeter enclosure, it protects workers from falls and shields the structure from wind, dust, and falling debris. Its climbing mechanism allows the system to ascend with each floor slab, maintaining continuous protection throughout the vertical build. The modular design allows easy installation, repositioning, and compatibility with various structural configurations. Ideal for tower construction and tall buildings, the ACS Safety Screen System enhances safety standards while enabling faster and uninterrupted work at height.

Shoring System

*Image Will be uploaded soon

S80 Shoring System

The S80 Shoring System is a modular, heavy-duty support solution tailored for large-scale construction projects including bridges, tunnels, industrial structures, and high-rise buildings. Engineered with galvanized steel components and a reliable ring-lock design, it delivers exceptional load-bearing capacity and structural stability. The system’s modular nature ensures easy assembly, adaptability to various site conditions, and efficient vertical support during concrete casting. Designed for repeated use, it withstands harsh environments and minimizes setup time. Whether supporting complex geometries or large slab areas, the S80 system provides the strength, flexibility, and safety needed to meet demanding construction timelines and structural requirements.

S100 Heavy Duty Shoring System

The S100 Heavy Duty Shoring System is a powerhouse solution engineered to support extreme loads in complex, large-scale construction environments. Ideal for bridges, high-rises, and industrial structures, it features a modular design with high load-bearing capacity and quick, tool-free assembly. Built with precision-engineered components, the system ensures maximum stability and safety during concrete pouring and slab support. It adapts seamlessly to varying site geometries and project heights, making it suitable for both standard and custom applications. Designed for durability, reusability, and ease of deployment, the S100 delivers strength, reliability, and efficiency where it matters most—on your most demanding projects.

Enquire Us

Reach out to us for any inquiries, consultations, or project collaborations.